Technical Paper

-

Dynamics Vibration Prediction and Comparison with Downhole Data Measurements in Unconventional Wells

Excessive vibrations may induce equipment failures. It is crucial to accurately model the drillstring dynamics in order to help drilling engineers make better decisions and…

-

Early Identification of Drilling Collision Risk Using MWD Survey Quality Data

Abstract By identifying changes in the error characteristics of magnetic surveys while drilling, crews can be alerted early on to a potential close approach with…

-

Empirical Analysis of Lateral Spacing Uncertainty in North America Due to MWD Survey Error

Abstract Lateral spacing in unconventional plays can have a significant impact in the economics of field development (Bharali et al., 2014; Lalehrokh & Bouma, 2014).…

-

Enhanced Wellbore Placement Accuracy Using Geomagnetic In-Field Referencing and Multi-Station Correction

Abstract Reduced lateral spacing in congested oil and gas fields requires advanced techniques to prevent collisions while drilling. Anti-collision separation factors depend on the accuracy…

-

Ensuring Success of Complex Liner Deployment Over Complete Field Development Campaign

Abstract This paper describes the innovative engineering workflow which has been used to ensure the safe deployment of deep production liners on long step-out wells…

-

Fatigue Tracking for Mud Motors and MWDs in Unconventional Wells

Abstract As the industry continues to drill increasingly complex wells, the demand put on drilling equipment has increased and will continue to increase. Preventive maintenance…

-

Challenges and Solutions for Accurate Wellbore Placement in the Barents Sea

Abstract As development of the Barents Sea continues with new plays such as the Castberg, accurate specification of the local magnetic field is important to…

-

Fluid Circulation Effects on Torque and Drag Results, a New Take on an Old Subject

Abstract The hydraulic effects on torque and drag modelling have been thoroughly studied in the past, yet their interpretation still causes a lot of misunderstandings…

-

Foothills Drilling Performance Improvement – A New Transversal Approach

Abstract Total E&P initiated a drilling campaign in 2018 near the foothills of Bolivia where wells can be extremely challenging and lengthy to drill. These…

-

Casing Wear and Stiff String Modeling Sensitivity Analysis – The Contribution of DP Pipe-Body and Tool-Joint on Casing Contact

Abstract Casing wear due to pipe body and tool-joint of Range 2 and Range 3 DP is compared using a stiff-string torque & drag &…

-

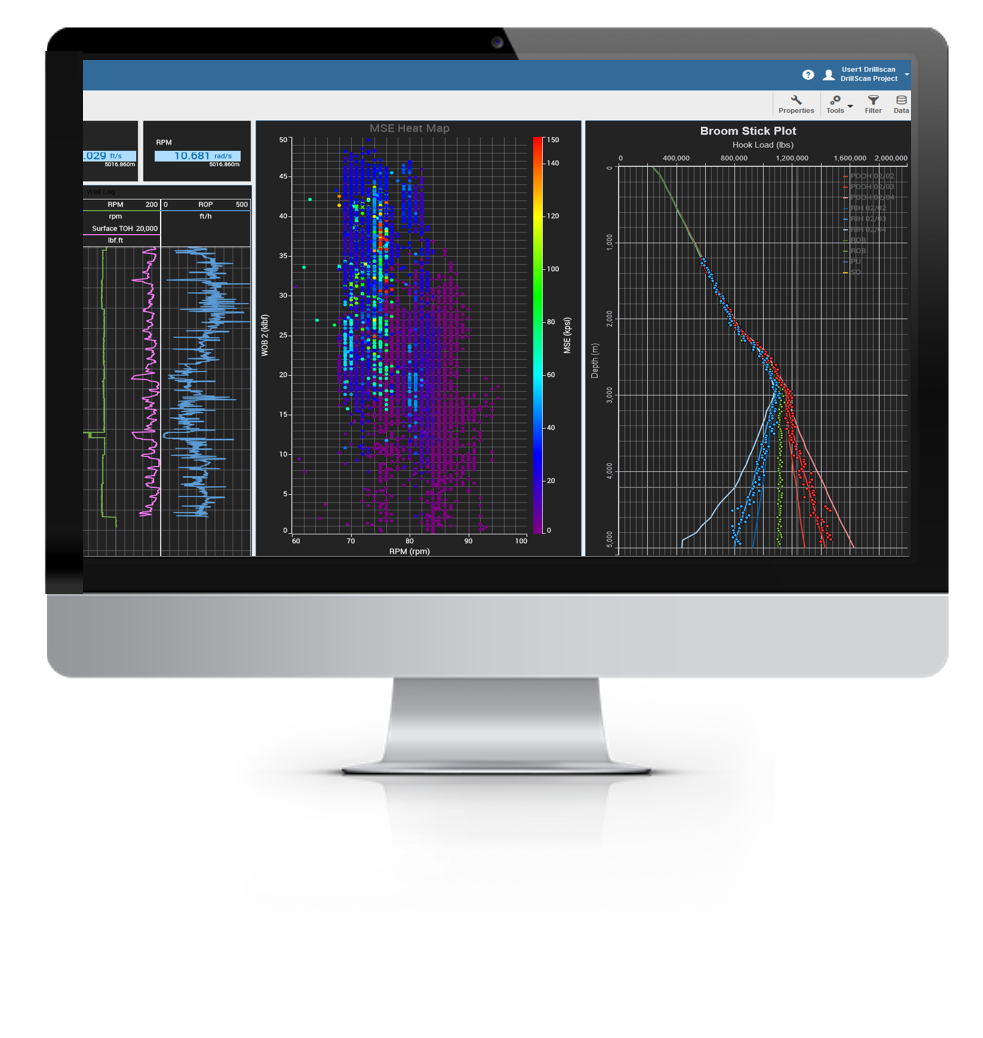

Holistically Leveraging Automation Technologies Across a Uniform Suite of Rigs

Reducing human variability bridges the gap between past performance and maximum theoretical performance.

-

How Drillstring Rotation Affects Critical Buckling Load?

Abstract Buckling of tubulars inside wellbores has been the subject of many researches and articles in the past. However, these conservative theories have always followed…