Technical Paper

-

Modeling the Effect of Axial Oscillation Tools in Torque and Drag Computations

Abstract When drilling complex wells, such as those with long lateral sections, the friction forces become significantly high, which can impede advancement of the drill…

-

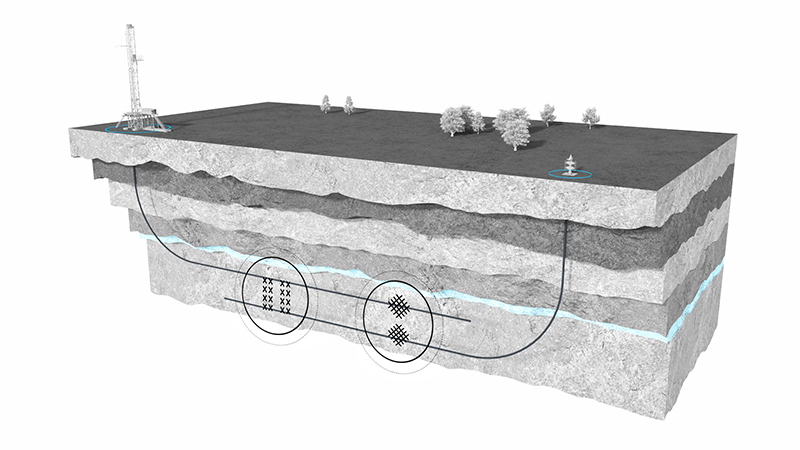

Modelling the Economic Impact of Spacing Uncertainty in Unconventional Long Laterals Due to Common Survey Practices

Abstract Finding an optimal lateral spacing is crucial to maximizing the return on investment for unconventional assets. The estimates regarding these lateral spacings were made…

-

Nonlinear Dynamics of a Drillstring Immersed in a 3D Curved Well, Simulations and Experiments

Abstract During drilling operations, the bit-rock and drillstring-wellbore contacts with stick-slip phenomena, fluid structure interaction, and mass unbalances distributed along the drillstring yield nonlinear dynamics…

-

Optimizing Lateral Well Spacing by Improving Directional Survey Accuracy

Abstract Optimizing lateral well spacing is a challenging problem that has significant economic consequences. The intent is to drill the fewest number of horizontal wells…

-

Optimizing Wellbore Trajectories for Closed Loop Geothermal Operations

Closed-loop geothermal presents a unique opportunity, with relatively few constraints to satisfy (e.g. target depth, lateral length). This study uses this freedom in trajectory design…

-

PDC Bit Steerability Modeling and Testing for Push-the-bit and Point-the-bit RSS

Abstract The footage drilled with rotary steerable systems (RSS) has increased significantly these last few years, due notably to the highly complex wells drilled today.…

-

Axial Force Transfer of Buckled Drill Pipe in Deviated Wells

Abstract Axial force transfer is an issue in deviated wells where friction and buckling phenomenon take place. The general perception of the industry is that…

-

Real-Time Directional Survey Quality Improvement Using Web-Based Technologies

Abstract Optimal wellbore placement and collision avoidance requires accurate real-time steering of directional wells. Uncertainties in the wellbore position are accounted for by industry standard…

-

RSS and Motor Directional Analysis: Modelling the Effect of Local Doglegs on RIH of Completions and Casing

Abstract Rotary steerable systems (RSS) and steerable motors pose their own unique challenges when modelling the bottomhole assembly (BHA) directional behavior. This paper aims to…

-

Simulation of Recovery Losses Due to Positional Errors in Wellbore Placement

Abstract In unconventional resources, horizontal wells are drilled in parallel at a spacing distance designed to maximize drainage of the reservoir. Lateral well spacing should…

-

Simulation Validation, Calibration and Fidelity of a Dynamic Downhole Drilling Phenomenon

Abstract This paper presents the simulation of a dynamic downhole drilling phenomenon which resulted in significant non-productive time and unnecessary drilling cost. The consistency of…

-

Stiff String Casing Design: Tortuosity and Centralisation

Abstract The forces and stresses along casing strings are modeled using a stiff string torque and drag model. The effect of wellbore tortuosity and centralization…