How RFA Slashed Drillpipe Deformation by 60%

PROJECT OVERVIEW

Location: Permian Basin

Outcomes: Enhance Bit & BHA Integrity, Increased Reliability, Reduced Human Variability

Tubular Connections Up To 100,000 ft-lbs. and Break-Out Connections at 120,000 ft-lbs.

Overview

Since the beginning of the shale revolution in the early 2000’s, we have seen significant changes in how wells are drilled. As operators continue to iterate and drill longer laterals with premium connections and larger pipe, we will continue to see a need for higher torque ratings in all aspects of downhole equipment. Achieving higher torque ratings require new solutions to streamline the process of breaking high-torqued equipment without sacrificing safety, speed or equipment life.

Challenge

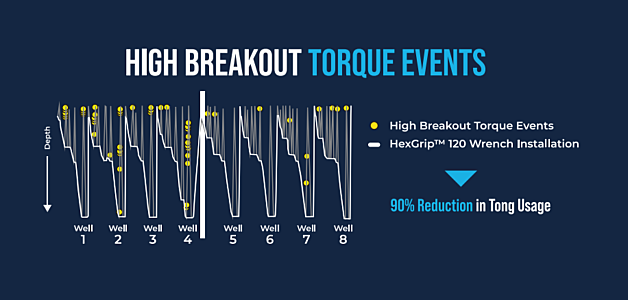

An exploration and production (E&P) company with operations in the Midland Basin was battling over-torqued connections and trying to mitigate the resulting drillpipe damage. Between Q3 and Q4 of 2021, a considerable number of their drilling connections had to be broken with manual tongs. In addition to slowing the connection process down and reducing the life of the drillpipe, a larger threat was the added safety exposure. With tong events attributing to a large percentage of crew time in the red zone, they knew they needed a new solution that could break connections at a higher torque than 60,000 ft-lbs.

Solution

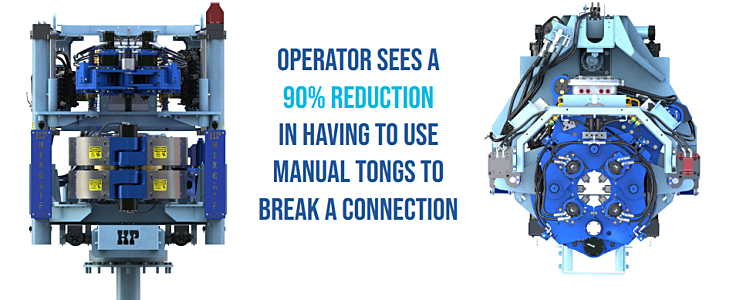

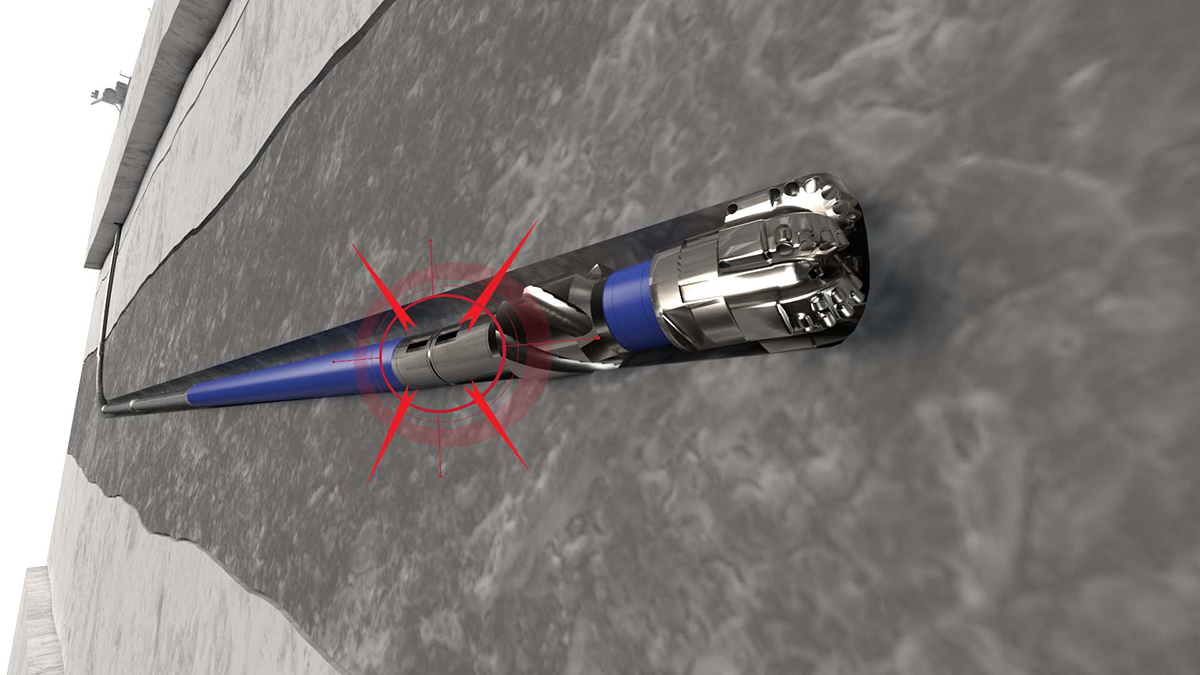

H&P introduced the HexGrip™ 120 wrench, a newly released proprietary tool designed to help solve the torque challenges the industry is facing and provide ancillary benefits to operators. This high-torque automatic wrench is capable of making tubular connections up to 100,000 ft-lbs. and breaking out connections at 120,000 ft-lbs., making it ideal for long lateral applications that require higher torque. Its centrifugal grip has 6 dies in a 360° pattern to hold the tool without egging the tubular box – leading to 60% less deformation when applying force to the drillpipe. With the touch of a button, it enables remote control automation of a tubular connection, reducing human interaction and the possibility of an accident.

With the HexGrip 120 wrench, the operator was able to collect a host of data points that provided analytics of tubulars and downhole dynamics. This list included make-up and break-out torques to help ensure that the pipe was torqued to specification and to identify any over torque events downhole.

Outcome

The operator saw a 90% reduction in manual tong usage over six months when compared to the previous six months, prior to installation. This led to 14 less tong events per well, or an average of one hour of savings per well. It also recorded a breakout up to 103,000 ft. lbs. and had an extremely low variance in make-up torques. After 10,000 connections were made and broken, the HexGrip 120 only averaged a 0.21% deviation from intended torque, delivering more precise, consistent connection make-ups. Most importantly, with enabled automation, crew members interacted with the tool significantly less, reducing the exposure level of the drill floor.

Past performance is not a guarantee of future results. Any statements regarding past performance are not guarantees of future performance and actual results may differ materially. © 04/2023 HPCS021

Related Case Study

-

By Mitigating Motor Failures and the Associated Time Lost, Operator Saved $105,000 Per Well

H&P Technology Helped Increase Lateral Slide ROP by 120% and Make a One-Run Lateral Curve Possible

-

Operator saves 2.38 days of drilling time, equating to a savings of over $140,000 per well

Head-to-head comparison proves science-based directional drilling approach enhanced bit and BHA integrity and reduced time to target Challenge A major operator was drilling in the…

-

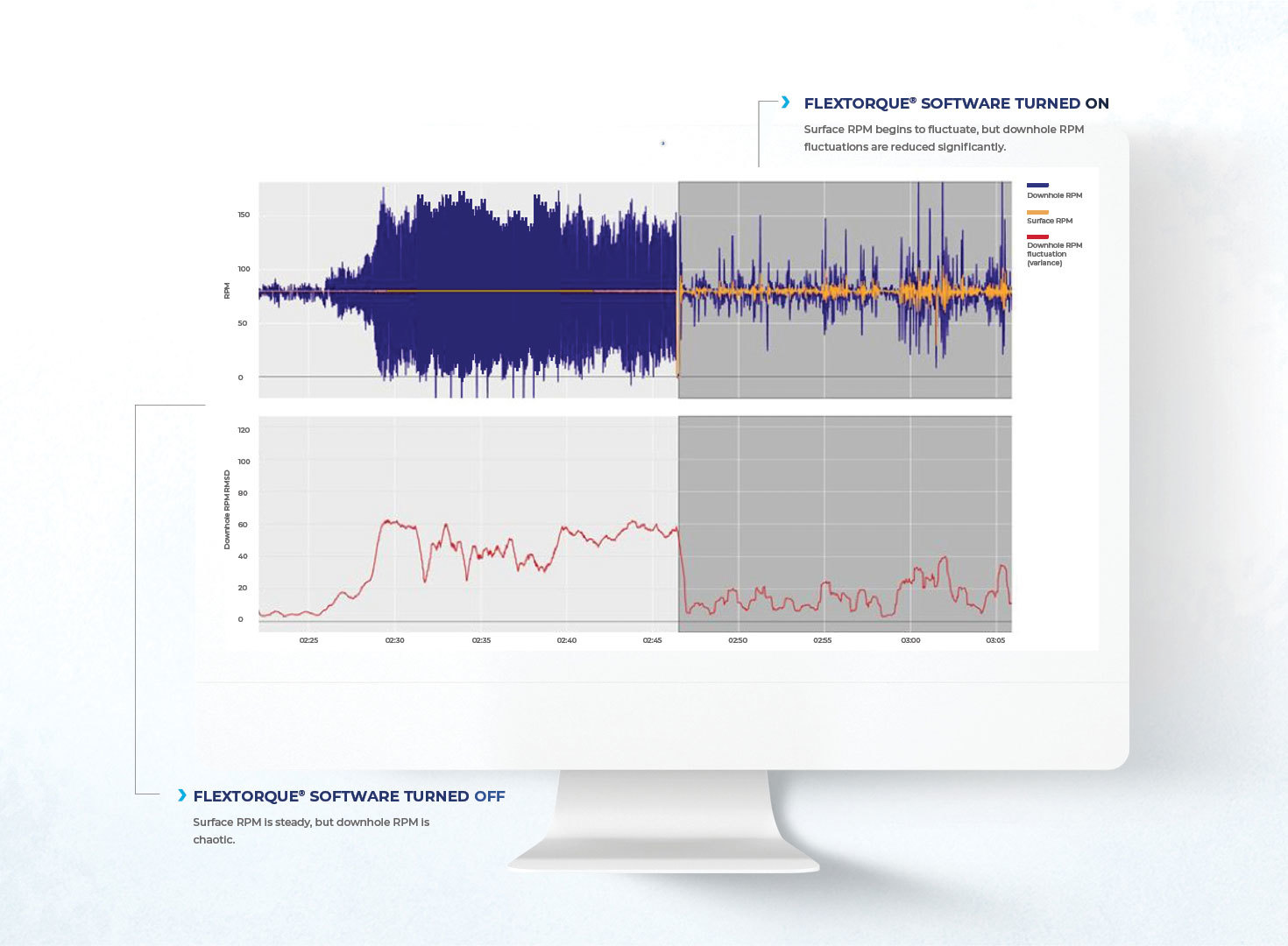

Operator increases rotating ROP and enhances bit and BHA integrity with Flexdrill® technology

Challenge An operator drilling out of the Meramec formation in Oklahoma historically struggled with suboptimal rates of penetration (ROP) due to stick slip and whirl.…

Related Product Literature

-

FlexB2D® 2.0 technology | Fact Sheet

Fill out the form below to access the fact sheet

-

StallAssist® software | Fact Sheet

Detect, mitigate, and recover from downhole stalls This technology can help decrease sidetracks or lost in hole occurrences and increase motor and bit longevity, translating…

Related Technical Publications

-

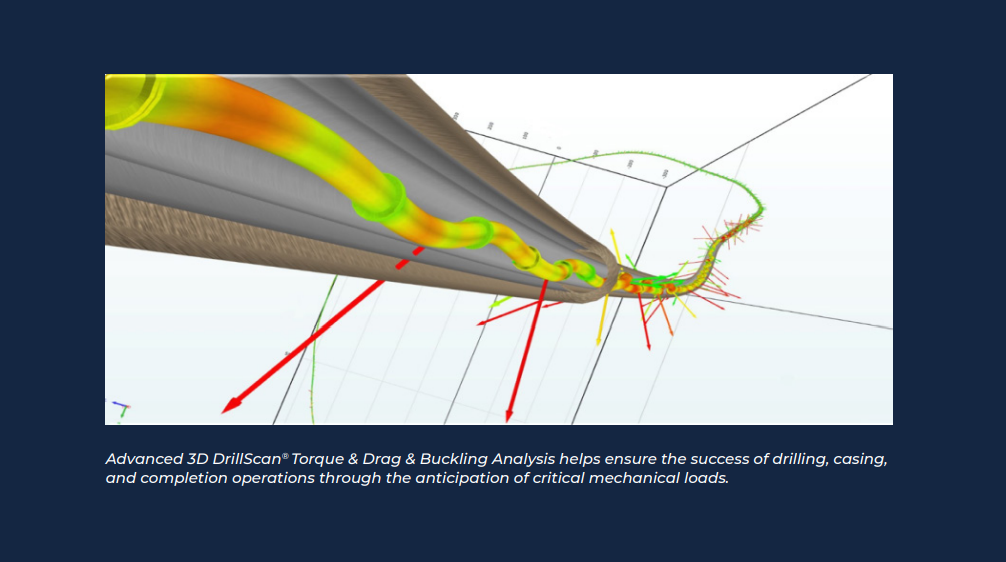

Casing Wear and Stiff String Modeling Sensitivity Analysis – The Contribution of DP Pipe-Body and Tool-Joint on Casing Contact

Abstract Casing wear due to pipe body and tool-joint of Range 2 and Range 3 DP is compared using a stiff-string torque & drag &…

-

Fatigue Tracking for Mud Motors and MWDs in Unconventional Wells

Abstract As the industry continues to drill increasingly complex wells, the demand put on drilling equipment has increased and will continue to increase. Preventive maintenance…

-

Learning Curve Benefits Resulting From the Use of a Unique BHA Directional Behavior Drilling Performances Post-Analysis

Abstract With the current market’s high prices for drilling units and sophisticated directional and formation assessment services, low systems reliability or poor directional performance in…