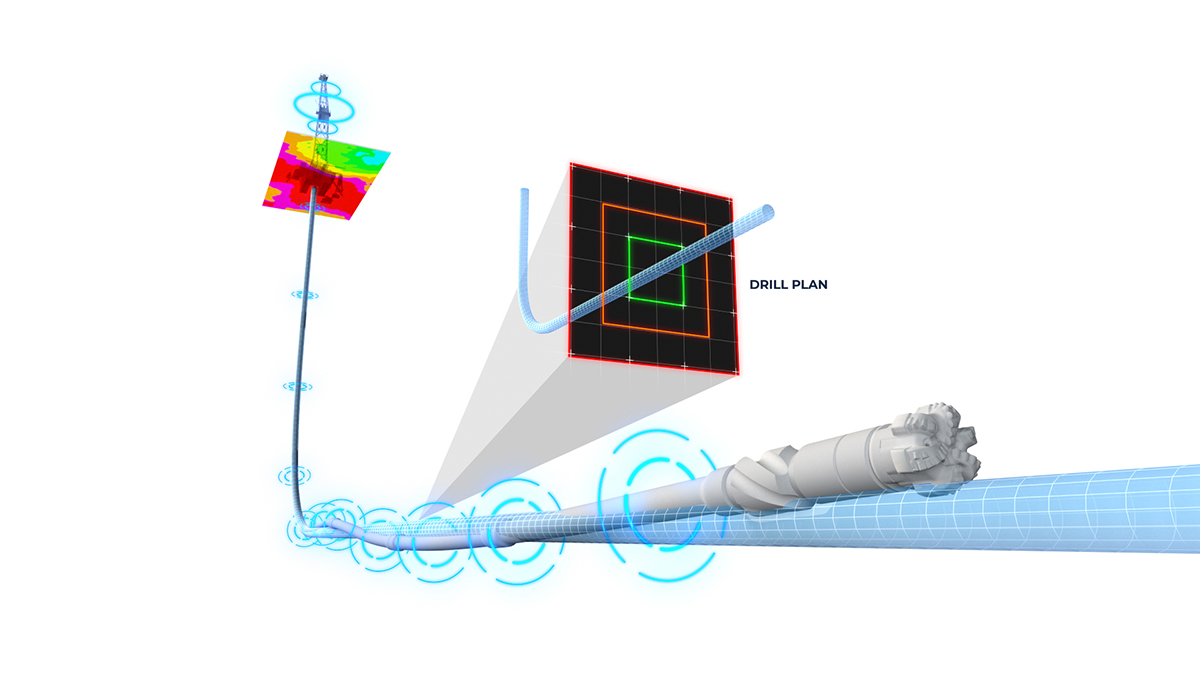

Digital Roadmap® technology

Automatic upload & execution

Outcomes

- Efficiency & Optimization

Compatibility

- FlexRig® Fleet

H&P’s Digital Roadmap® technology allows users to automatically load drilling parameters, even from remote locations, into the control system based on geologic formation, depth, and geometry to reduce time consuming, manual changes and potential inaccuracies

- Increased Visibility

- Automatic Roadmap Execution

- External Control

Features & Benefits

Remote Roadmap Access

Benefit

Real-time visibility into drilling parameters and tech updates from anywhere.

Power User Controls + Unlimited Viewers

Benefit

Full-team awareness and control – Operators and H&P users can edit or view the roadmap as needed.

Roadmap-to-Rig Automation

Benefit

Seamless execution – Syncs to the rig for auto-execution of parameters as drilling progresses.

How it Works

The workflow around drilling roadmaps that exists today is a manual process that lacks real-time communication amongst relevant stakeholders. H&P’s Digital Roadmap® technology allows users to view, plan and edit a roadmap remotely and enables the automatic execution of that roadmap. By enabling the automatic execution of these parameters, which are based on geologic formation and depth, Digital Roadmap technology helps reduce the time needed for manual inputs and decreases the potential for inaccuracies.

Works Seamlessly With

Digital Roadmap Technology streamlines drilling by integrating autonomous, data-driven tools that reduce variability and support more consistent execution.

When paired with H&P’s failure prevention technologies shown below, this solutions suite helps limit BHA damage and keeps drilling on track.

FlexB2D® 2.0

Ensures controlled, efficient re-engagement of the bit to bottom.

FlexTorque®

Actively adjusts top drive RPM in real time to mitigate stick-slip.

Autodriller Pro

Regulates block speed using torque, WOB, and differential pressure inputs to maintain steady bit engagement

Automation Sequencer

Sequenced collaboration between our advanced drilling technologies allows for more robust solutions without manual changes.

StallAssist®

This technology boosts bit and BHA reliability to minimize downhole stalls, reduce sidetracks, and maximize footage drilled—all helping reach target depth faster.

Supporting Resources

Ready to learn more?

Discover how Digital Roadmap® technology works to unlock peak performance, precision, and efficiency.

Send a message